IET Completes Largest Implimentation of NAPL Stabalization Technology

October 7, 2015 (Gainesville, Florida)

Innovative Environmental Technologies Inc. (IET) is proud to announce the completion of the largest implementation of an novel and innovative in-situ NAPL stabilization process. The project, in Gainesville, Florida was completed on-time and under budget.

Over a three month period, IET manufactured and injected over 167,000 gallons of stabilization material at a former creosote facility targeting free-phase creosote present between 15 and 60′ bgs. The technology entails the use of modified permanganate solutions for the purposes of mass removal and flux reduction (i.e., NAPL stabilization). As the oxidant migrates through the treatment area, various geochemical reactions destroy the targeted compounds present in the dissolved phase. This causes a “hardening” or “chemical weathering” of the NAPL as it steadily loses its more labile components. This causes a net increase in viscosity of the organic material, which yields a more stable, recalcitrant residual mass. In addition, both the insoluble MnO2 precipitate that results from permanganate oxidation and other mineral species included in the stabilization crystalline material. These form and accumulate along the NAPL interface, physically coating the NAPL and thereby reducing the flux of dissolved-phase constituents of interest (COI) into the groundwater.

“With this project, IET has again demonstrated our field capabilities”, states Michael Scalzi, President of IET.

“With this, and our dozen patented and proprietary technologies, IET further establishes ourselves as the premier injection and technology vendor in the United States. Since 1998, we have designed and implemented over 1,200 projects, ranging from heavy metals treatment, chlorinated solvent remediation, petroleum hydrocarbon biotic/abiotic mineralization and PAH stabilization.”

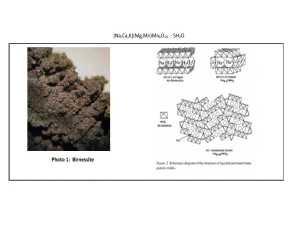

Confirmation of the formation of the Birnessite-like crust.